In this article, you will learn:

- how are autonomous mobile robots and automated guided vehicles transforming warehouse operations?

- what are the differences between AMR and AGV?

- what are the key benefits of autonomous robots for a facility?

- what does it mean that AMR and AGV are key to Manufacturing 4.0?

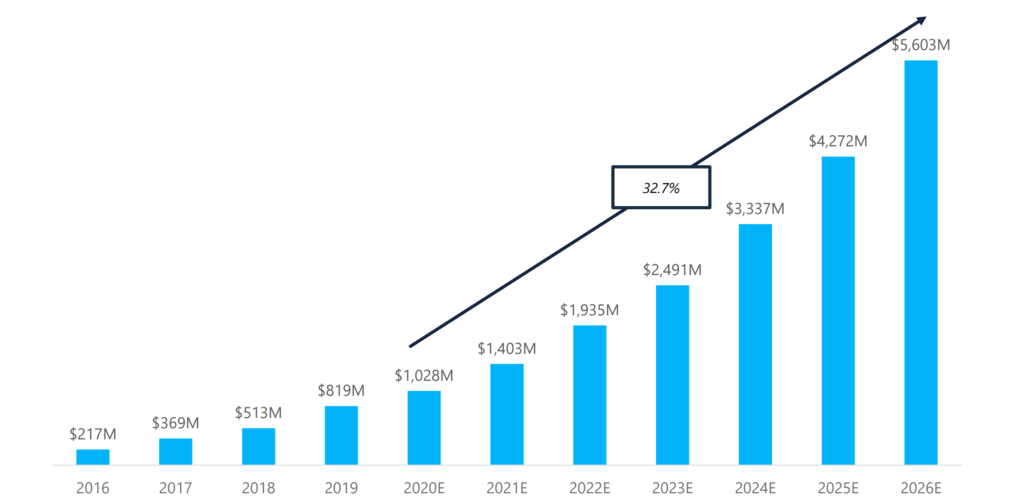

In the innovative landscape of industrial automation and smart logistics, the advent of Automated Guided Vehicles (AGV) and Autonomous Mobile Robots (AMR) has marked a transformative era in logistics and automation of warehouse operations. These pioneering warehouse robotics technologies, each with unique capabilities for autonomous navigation and automated material handling, are at the forefront of driving efficiency and innovation in supply chain automation. According to Logistics IQ Research, AGV and AMR are the fastest-growing segments, essential for fully automated warehouses, as shown in the chart below. It is estimated that by 2026, their market value will reach $5,603 million with a CAGR of 32.7% during the forecast period of 2020-2026.

LogisticsIQ Research, Warehouse Automation Market: Forecast to 2026 report

This article explores how AGVs and AMRs are reshaping warehouse automation and material handling, understanding their differences, benefits, and roles in Manufacturing 4.0 for enhanced efficiency and innovation in supply chain logistics.

AGV: Pioneering intralogistics automation with guided vehicles

AGVs have long been integral to industrial automation, offering precise and reliable automated material handling solutions. With advanced AGV navigation systems, these guided vehicles streamline operations across warehouse and manufacturing floors, enhancing intralogistics automation and safety standards. These industrial mobile robots are engineered with specific AGV control systems, making them ideal for repetitive tasks where routes are predefined, thereby optimizing the efficiency of robotics in manufacturing.

Key advantages of AGV in warehouse automation:

- AGV systems and safety: Incorporating rigorous AGV safety standards, these vehicles ensure secure operations within industrial environments.

- Automated material handling: AGVs excel in repetitive, structured tasks, offering unparalleled consistency in material handling and supply chain automation.

- Intralogistics automation: Through seamless AGV integration, businesses can significantly enhance intralogistics workflows, increasing overall productivity.

However, the reliance on predefined paths limits AGVs’ flexibility, posing challenges in dynamic environments where adaptability and real-time decision-making are crucial.

AMR: Elevating flexibility in warehouse automation with autonomous navigation

AMRs stand out for their sophisticated autonomous navigation capabilities to intelligently maneuver through dynamic environments. These mobile robotics solutions are equipped with advanced sensors, enabling collaborative robots to perform pick and place tasks, material handling, and fleet management with high efficiency and adaptability. AMRs epitomize the principles of Manufacturing 4.0 and smart logistics, showcasing how robotics automation can significantly enhance operational flexibility and productivity.

Key features of AMR:

- Collaborative robots and flexibility: AMRs collaborate seamlessly with human operators, adjusting their routes in real-time to navigate obstacles and optimize workflows.

- Smart logistics and fleet management: Leveraging mobile robotics, AMRs offer dynamic fleet management solutions, adapting to fluctuating demands and operational challenges.

- Autonomous navigation: Through advanced sensors and autonomous navigation techniques, our AMRs excel in complex environments, enhancing warehouse automation and robotics integration. They can avoid static and dynamic obstacles and operate safely close to human workers. Discover more about LIDAR navigation techniques and their role in powering our autonomous mobile robots.

- Equipment diversity: AMRs support various attachments for different cargo types, enhancing their utility and application range with adaptable coupling systems such as pins, lifting roller conveyors, or towing systems.

- Integration & scalability: AMRs navigate using preloaded maps for quick workflow integration without infrastructure changes. They are scalable, managing multiple units effortlessly and simplifying the addition of robots without the need for structural modifications. For example, Aformic’s Qursor system demonstrates this by managing 20 AMRs to complete 500 tasks in 8 hours. Check more about Qursor.

The adaptability and intelligence of autonomous mobile robot technology make them particularly beneficial for environments that demand flexibility and the capability to respond to real-time changes. Get to know about Aformic fleet of autonomous mobile robots series F here.

AGV vs. AMR: Navigating the future of industrial automation and smart logistics

Choosing between AGVs and AMRs for robotics in logistics and supply chain automation depends on the specific needs of the operation, including the demand for flexibility, autonomous vehicles’ integration, and the nature of the tasks. AGVs offer reliability and precision for repetitive paths, making them suitable for environments with stable layouts. In contrast, AMRs provide unmatched flexibility and adaptability, ideal for dynamic settings where obstacles and layout changes are common.Integrating AMRs into existing workspaces does not necessitate infrastructural changes, making their adoption more cost-effective. Furthermore, technological advancements render AMR solutions generally more affordable than traditional AGV systems in existing environments.

Conclusion

AGVs and AMRs are key to Manufacturing 4.0, facilitating the integration of autonomous vehicles and robotics in logistics with the broader Industrial IoT ecosystem. Their adoption not only boosts operational efficiency but also fosters innovation in robotic process automation and mobile robotics, shaping the future of manufacturing automation and smart logistics.