Menu

Close

Efficient task allocation, path planning, navigation, and performance monitoring. Qursor is the key to integrating autonomous robots in smart warehouses and manufacturing settings.

Eficient task allocation, path planning, navigation, and performance monitoring.

Asset tracking and equipment management via RTLS technology

Automated warehouse management & inventory tracking

Sail toward success!

Real-time tracking for efficient coordination, monitoring, and control of multiple robots simultaneously,

Obstacle avoidance for safe and efficient navigation,

Alternative path generation mechanism when autonomous obstacle avoidance by AMR fails,

3D target detection and docking to identify docking stations or designated targets for precise navigation and alignment.

CHECK HOW YOU CAN IMPROVE YOUR WORK EFFICIENCY AND STREAMLINE TASKS MANAGEMENT AND DELIVERY PROCESS WITH OUR QURSOR SYSTEM.

We offer flexible solutions tailored to your needs, whether you prefer ready-made or customized options.

Choose the packet that suits you.

| STANDARD | ENTERPRISE | CUSTOMIZATION | |

|---|---|---|---|

| Support for all F series AMRs | |||

| Integration 3rd party AMRs | |||

| Flexible route planning | |||

| Advanced traffic management | |||

| Intelligent mission management | |||

| Smart charging management | |||

| Real-time tracking of the whole system | |||

| Integration APIs (MES/WMS/WCS/others) | |||

| PLC connectivity | |||

| Customized integration API | |||

| Customized hardware connectors | |||

| Andon integration | |||

| Traffic zone blocking | |||

| Obstacle avoidance and alternative path | |||

| Doors status and control | |||

| Traffic lights control | |||

| Environmental awareness features (RTLS) | |||

| Heat map for different functions | |||

| Production statistics collection | |||

| AMR diagnostic tracking | |||

| Customized dashboards | |||

| Warehouse Control System |

The custom software package provides access to a wide range of data, including online process visualization, real-time information on stations, AMRs and currently executed operations.

AMR custom software package

Convenient access to a wide range of data

On-line process visualization

Real-time information on stations, robots and other factory equipment

AMR vehicle extended diagnostic

Graphical system and delivery process configurator

Delivery process real-time preview

BI analytic tools integration

Dashboard customization

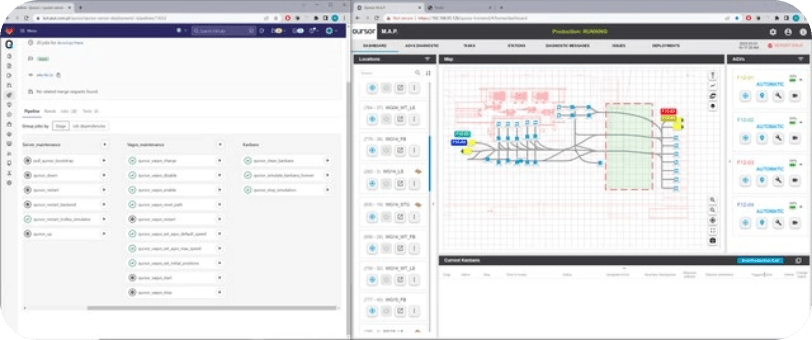

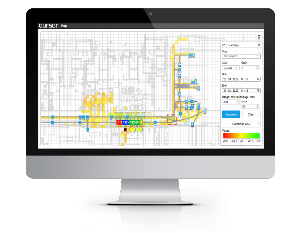

QURSOR M.A.P.

MANAGEMENT APPLICATION

remote control and overview of AMRs

process vizualisation with the current position of AMRs, stations, and paths

full insight into KPI modules (statistics, particular steps of the delivery) for current performance control of the system

complete diagnostic - causes of errors, AMR status check, availability of stations, location status, heatmaps, fault charts

tasks preview

AMR operation in zones

QURSOR M.A.P.

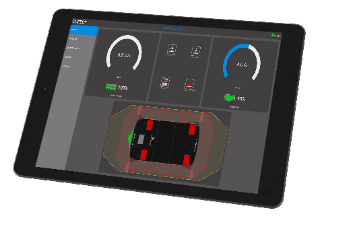

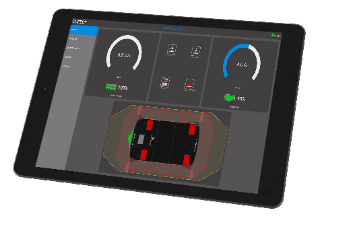

AMR HMI APPLICATION

graphical data presentation and control of AMRs

information about alarms, position status, speed, battery levels, and other functions of the AMR

HMI control panel accessed from a web browser or the LCD located on F robot

QURSOR

CONFIGURATOR

logistic process configuration

AMRs and conveyor settings

management of environment and map files

smart charger settings

traffic zones configuration

application parameters

QURSOR

TABLET APPLICATION

basic control and station diagnostic

task management

convenient control of AMRs

remote control and overview of AMRs

process vizualisation with the current position of AMRs, stations, and paths

full insight into KPI modules (statistics, particular steps of the delivery) for current performance control of the system

complete diagnostic - causes of errors, AMR status check, availability of stations, location status, heatmaps, fault charts

tasks preview

AMR operation in zones

graphical data presentation and control of AMRs

information about alarms, position status, speed, battery levels, and other functions of the AMR

HMI control panel accessed from a web browser or the LCD located on F robot

logistic process configuration

AMRs and conveyor settings

management of environment and map files

smart charger settings

traffic zones configuration

application parameters

basic control and station diagnostic

task management

convenient control of AMRs

FACILITATED MOVEMENT OF LOAD CARRIER WITHIN THE WAREHOUSE

FLEXIBLE WAREHOUSE STRUCTURE DEFINITION

WAREHOUSE VIZUALIZATION

WAREHOUSE LOADING/UNLOADING CONTROL

WAREHOUSE LOADING/UNLOADING RULES OR ALGORITHMS

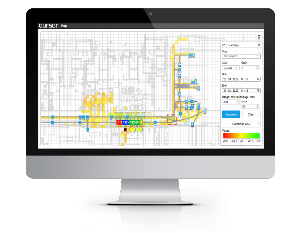

Efficient asset tracking and equipment management via RTLS technology

TRAFFIC LIGHT/TRAFFIC ZONE CONTROL

ENVIRONMENTAL AWARNESS

System simulation & virtual commissioning

Our robots are implemented using process simulation to test and optimize their behavior in virtual environments. Then, during the process of environment mapping, a digital model of the environment is created. The Qursor software allows for comprehensive management and control of all operating parameters of the system and its components.

Our system virtually simulates the solution prior to the physical implementation of the system using simulation software tools. Digital mapping of the system’s work environment and processes allows us to test the system before its actual implementation and further optimization. This is of key importance in the process of modeling routes or robot design.